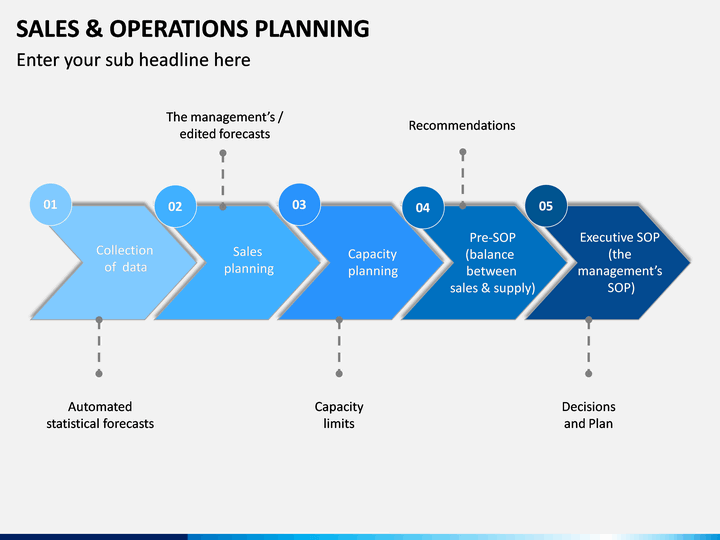

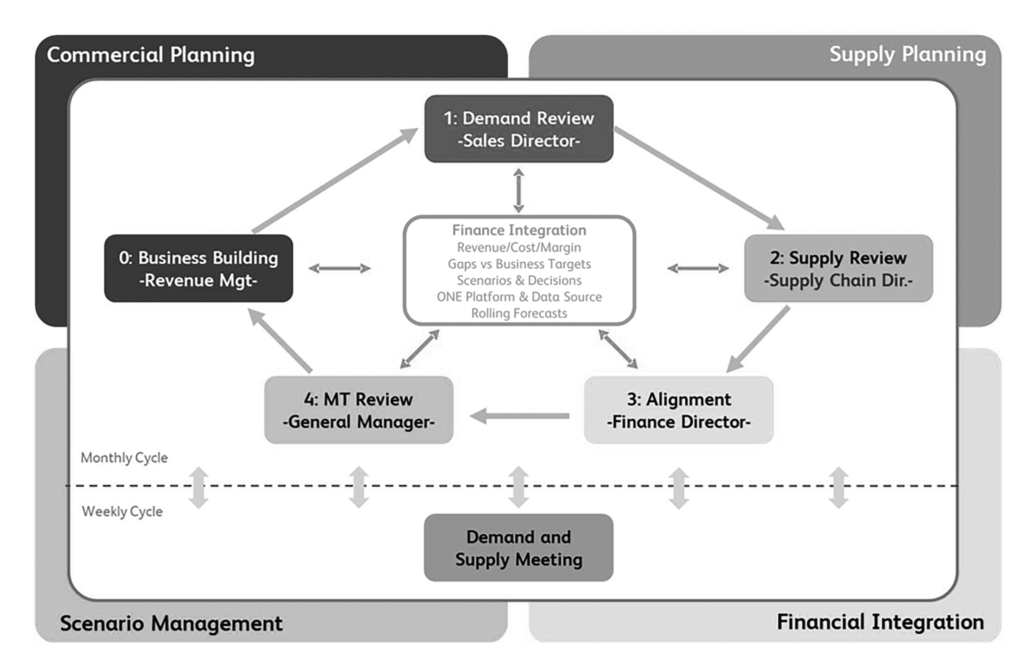

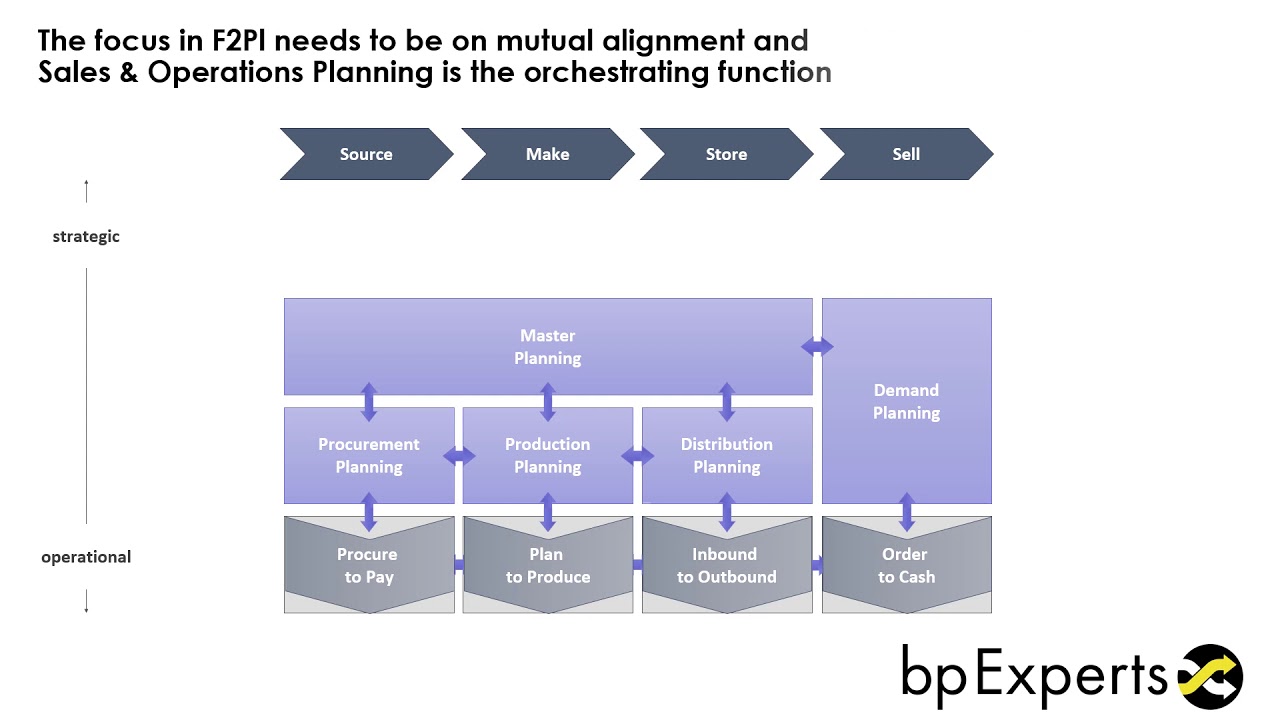

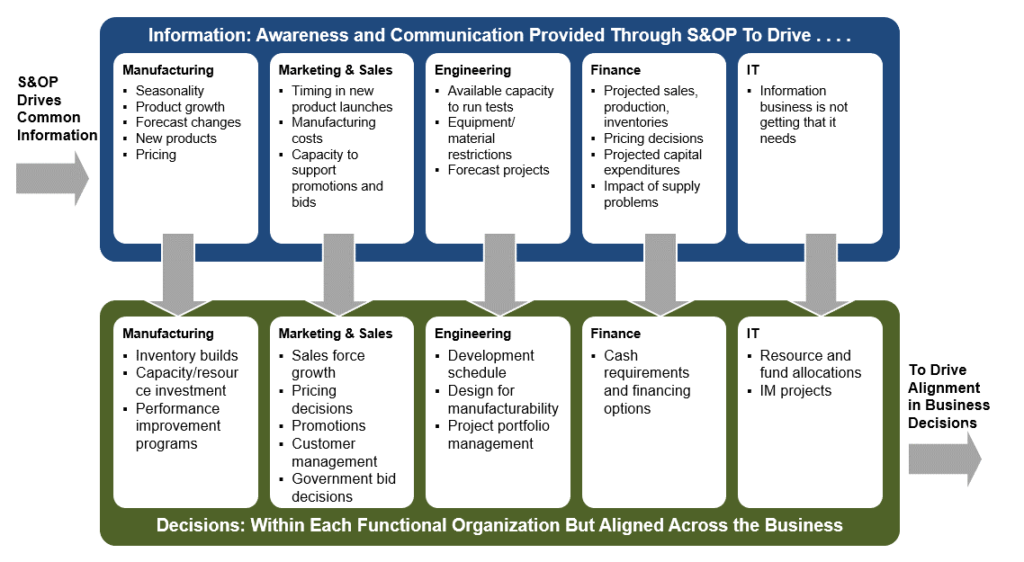

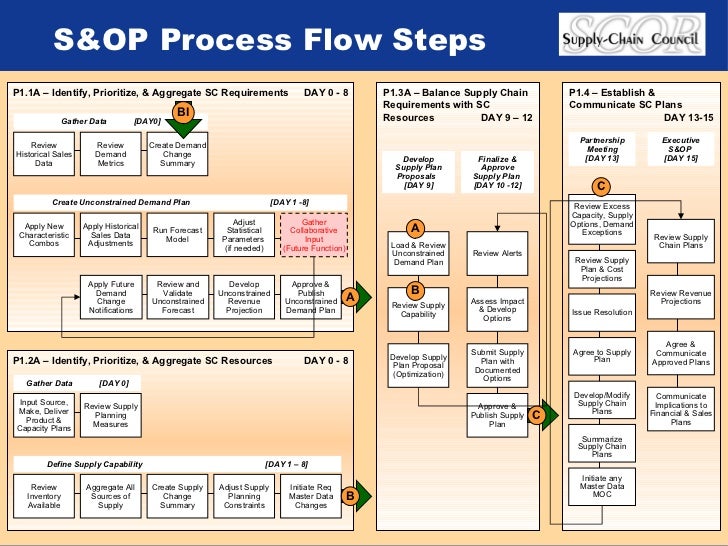

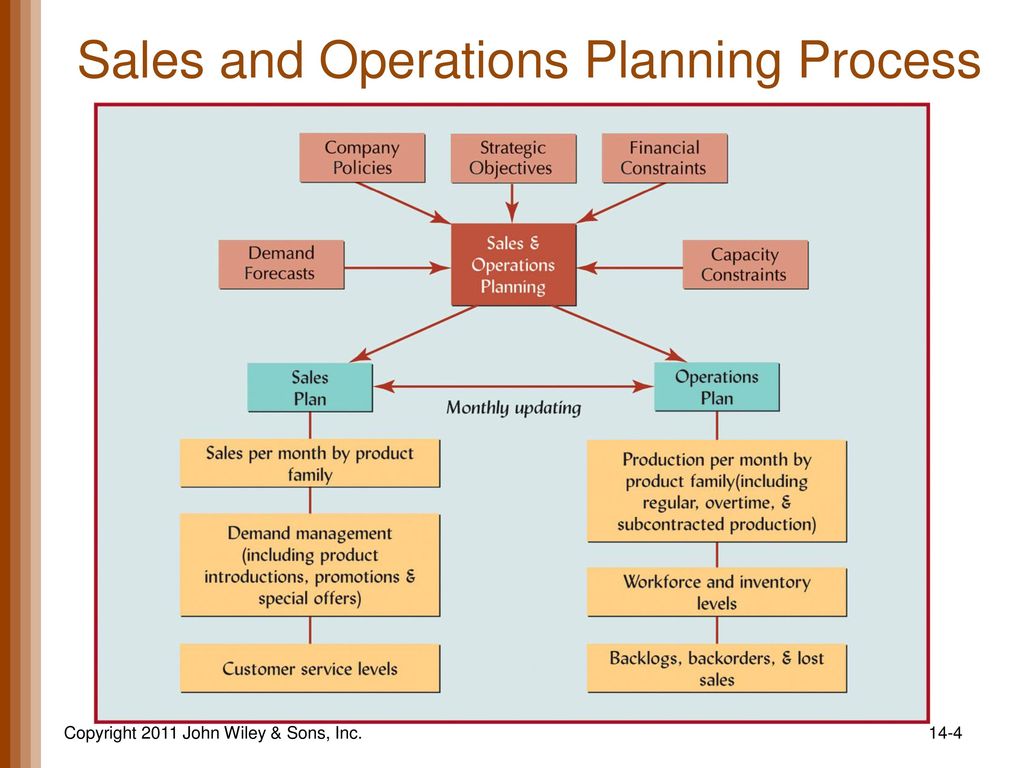

The S&OP process operates within the bounds of the goals, targets and strategic imperatives that have been passed down from the strategic planning processes These goals, targets and strategic imperatives act as guidelines throughout the S&OP process, ensuring that decisions are being made in alignment with the agreed strategic priorities Similarly, the aligned functional plans fromAn accountability tool to hold your sales guy to, they set the numbers after all ;S&OP process needs a strong foundation and requires the following to be established Establish, in writing, senior management support, clear organizational expectations, longrunning commitment, and positional empowerment Create and deliver value through optimal alignment of strategic goals and tactical execution of those goals that accounts for organizational strengths and pain points

S Op Effectiveness Recommendations To Make The Leap Sales And Operations Planning Planning Process Capacity Planning

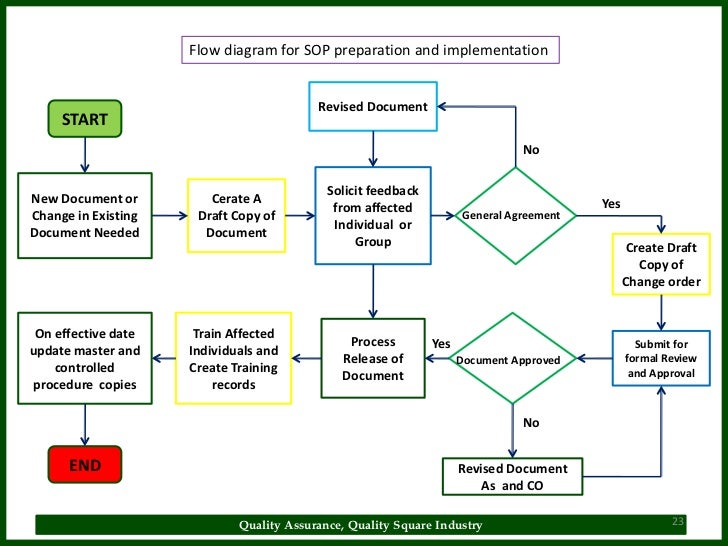

Sop process flow chart

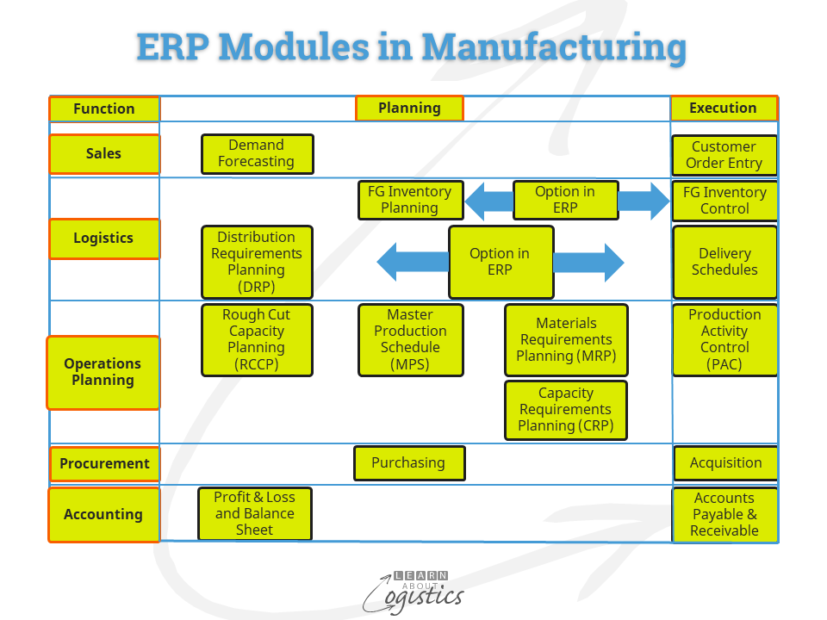

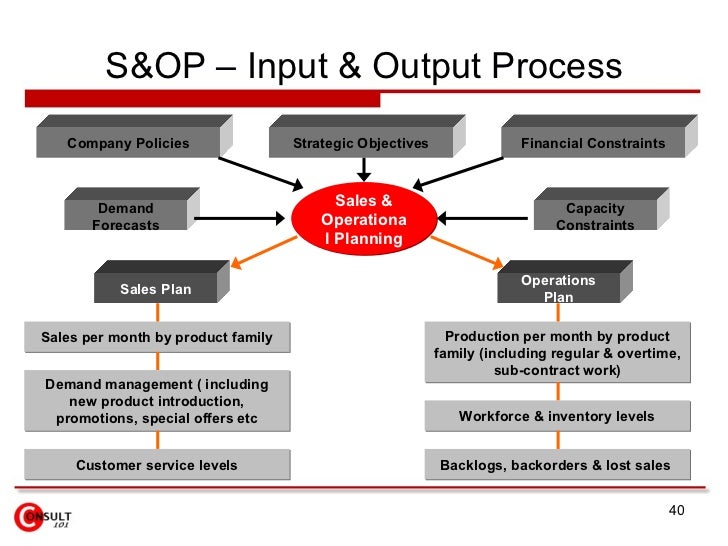

Sop process flow chart-S Op Process Flow Chart 1995 Chevy Suburban Wiring Diagram srd04actuator yenpancane jeanjaures37 fr Source srd04actuatoryenpancanejeanjaures37fr Best workflow apps review Process Street vs Tallyfy by Justin Ng Workflow Lab Medium Best workflow apps review Process Street vs Tallyfy by Justin Ng Workflow Lab Medium Source mediumcom Live Case Study Interview with ProcessS op process flow chart diagram Discrete Vs ERP Process ERP Discrete vs ERP Process People often ask what's the difference between process and discrete ERP?

Sales Amp Operation Planning Of Beer Supply Chains

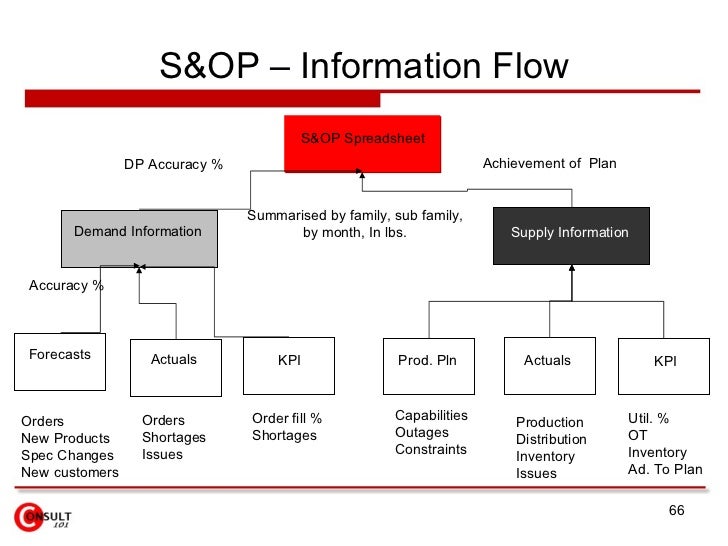

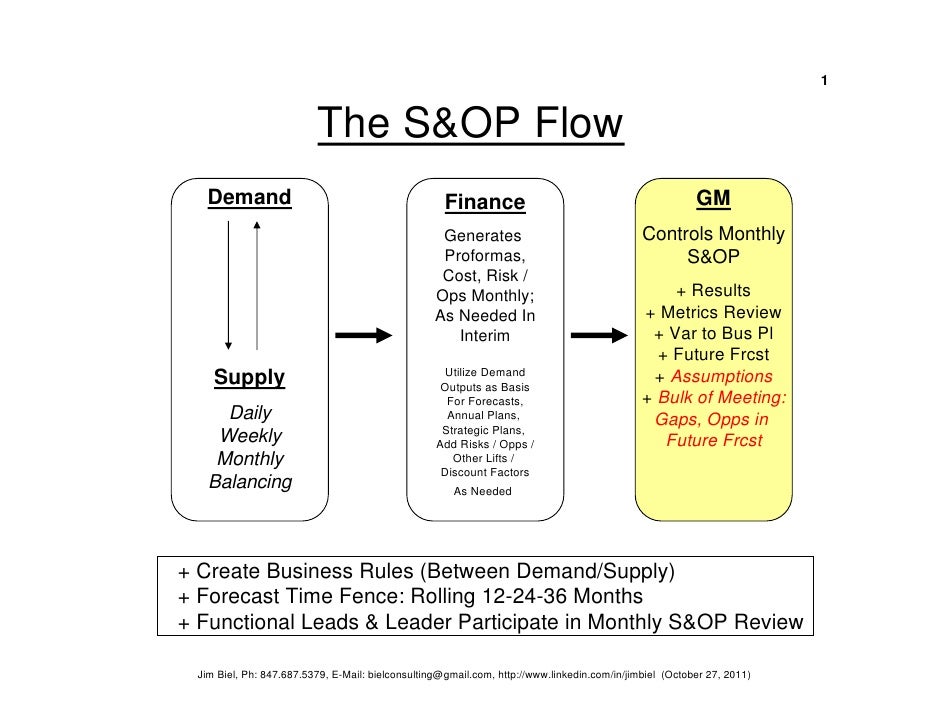

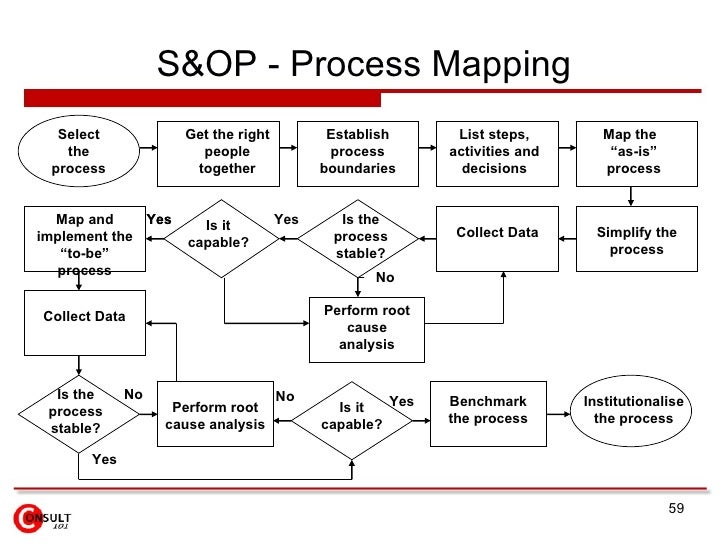

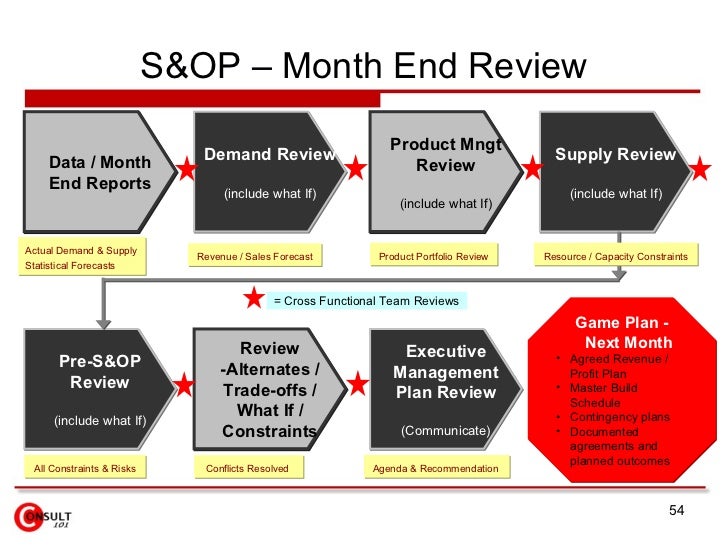

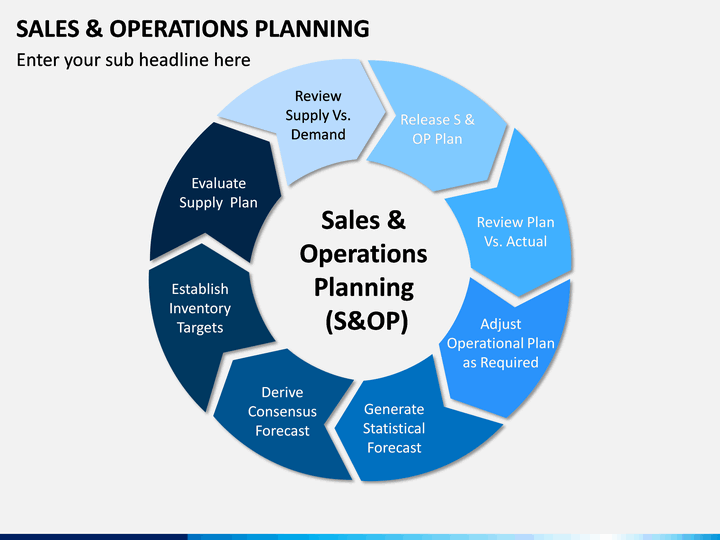

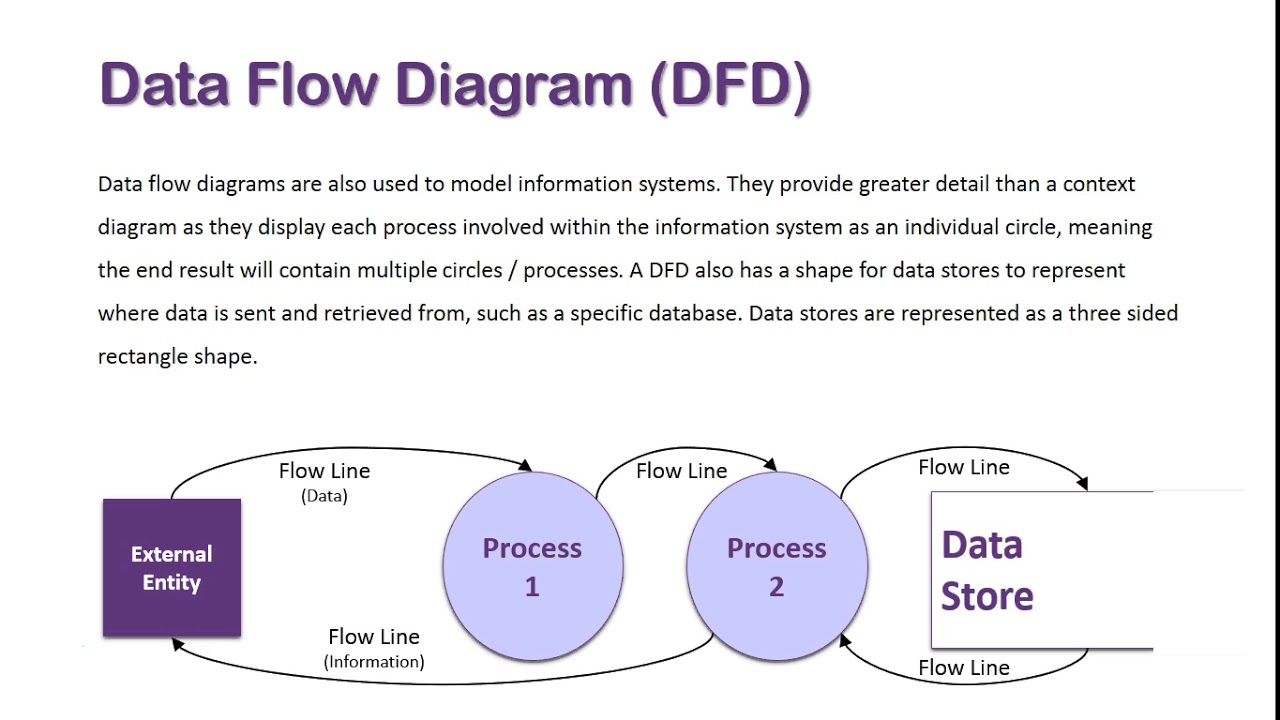

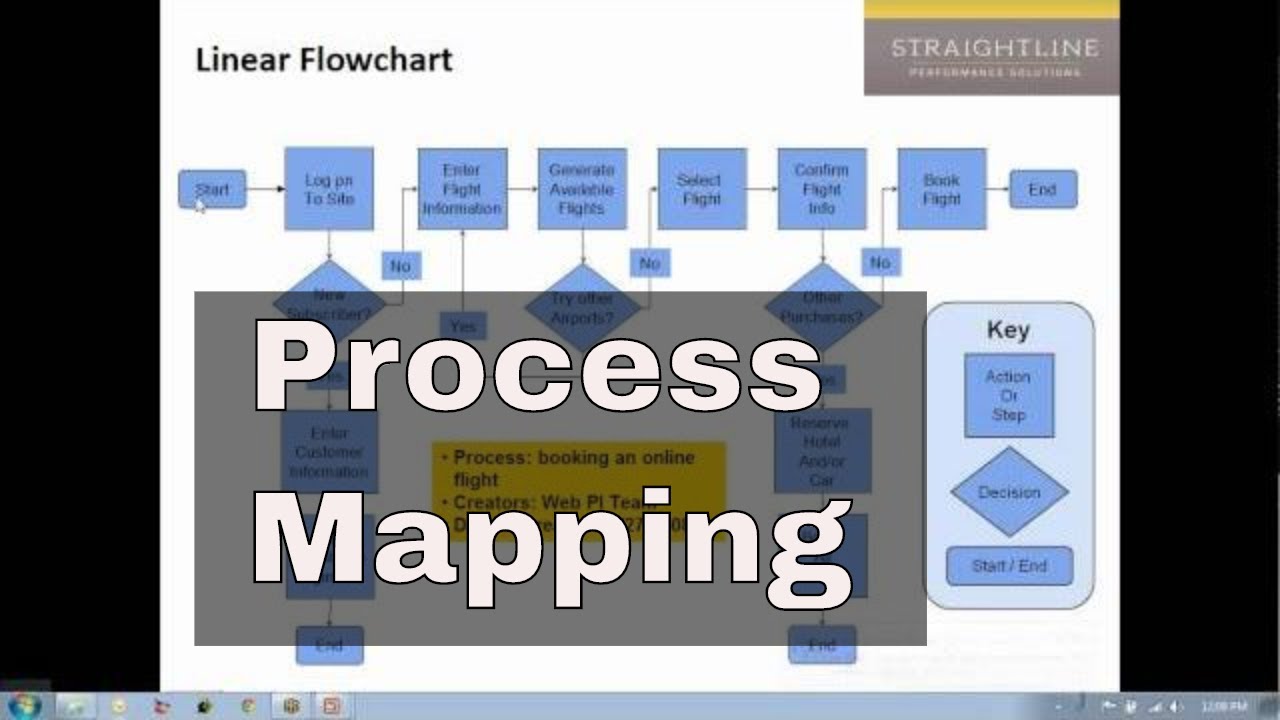

· Standard SOP Process flow Follow RSS feed Like 33 Likes 68,149 Views 22 Comments Sales & Operations Planning (SOP) is a flexible forecasting and planning tool with which sales, production, and other supply chain targets can be set on the basis of historical, existing, and estimated future data Use SOP to streamline and consolidate your company's sales and · Sales and Operations Planning (S&OP) is an integrated business process which enables the organization to formalize and integrate the planning process, achieve focus, and coordination among all · S&OP – Process Mapping (As~Is / To~Be) 55 S&OP Process Improvement Framework Continuous Improvement Identify Best Practices As~Is Analyse & Evaluate To~Be Implement Business Process Reengineer Business Process Improvement Approaches 56

· of S&OP As indicated by the other replies, Sales/Demand Planning is a key component of S&OP, but as some of the other replies have indicated, S&OP is more of a process that has to be adopted by key management to be truly effective S&OP is not a system however, as other replies have indicated, although you can purchase S&OP applicationsSteel Pipe Manufacturing Processes mandrel mill process plug mill process electric weld pipe process April 21 Mandrel Mill process Disimpan oleh jiwon Jeong 1 Heating And Cooling Extrusion Chemical Analysis Process Cool Stuff Stainless Steel Manufacturing Visual Manufacturing Informasi lainnya Lainnya seperti ini PrivasiGet Our EBOOK HERE A Sales, Inventory and Operations Planning (SIOP) business process is an essential element for running a successful business SIOP will allow you

· Which metrics are most crucial for SIOP (sometimes referred to as S&OP or sales and operations planning)?Establishes regular meetings with senior executives · 4 Challenges in Starting and Sustaining a SIOP (S&OP) Business Process!

S Op Heuristics Flow Chart Download Scientific Diagram

Supply Chain Management Principles Examples Templates Smartsheet

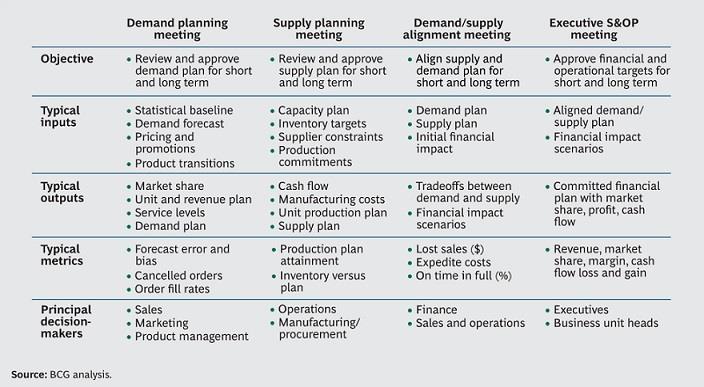

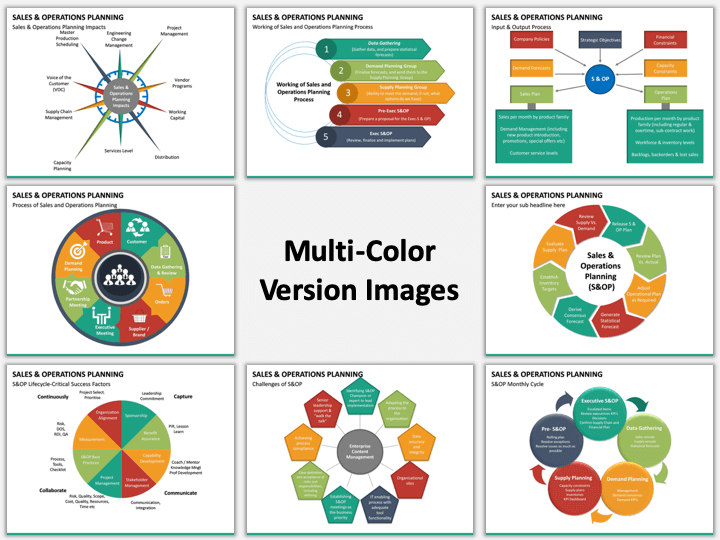

This presentation is intended for use as workshop material to introduce Sales & Operations Planning (S&OP) to all the senior management with activities to include the current way of silo planning and proposed way of collaborative planning It has 60 slides in all split in to 2 parts, presentation and a case study Contents S&OP Definition Linkages to S&OP and benefits of S&OP The SMAP ProcessIt is not an inventory replenishment tool!Comprehensive S&OP Planning Cycle When plans are disconnected, different planners tend to apply their own judgment which can result in both excess inventory and customer shortages By integrating the detailed planning steps with executive review through the S&OP process, the concept of a single plan is realized This single plan is utilized for demand, inventory and supply

Swim Lane Template Cross Functional Flowchart

Achieve Excellence In Sales And Operations Planning Sapinsider

Apr 3, 17 The garment manufacturing process and a detailed process flow chart on garment manufacturing are displayed in this post · This process involves the monitoring of stocks and, in particular, the automatic creation of procurement proposals for purchasing and production In doing so, MRP tries to strike the best balance possible between "optimizing the service level and minimizing costs and capital lockup" The MRP component (PPMRP) assists and relieves MRP controllers in their area ofFast, effective process to assess the operations & financial impact and the best possible response v Single, organization wide demand & supply planning vi High costs savings leveraging effect in eg working capital ÌNDUSTRY CHARACTERISTICS S&OP BENEFITS Page 13 Agenda • What is Sales & Operations Planning (S&OP) • Definition, purpose & planning hierarchy • Organizational

S Op Sales And Operations Planning And Sco

S Op Process Flow Diagram 02 Gmc Yukon Xl Wiring Diagram Oonboard Gaati Loro Jeanjaures37 Fr

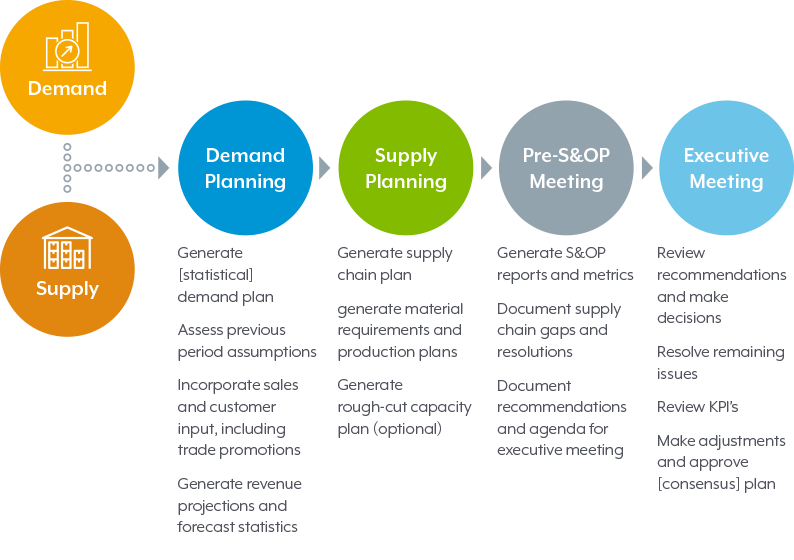

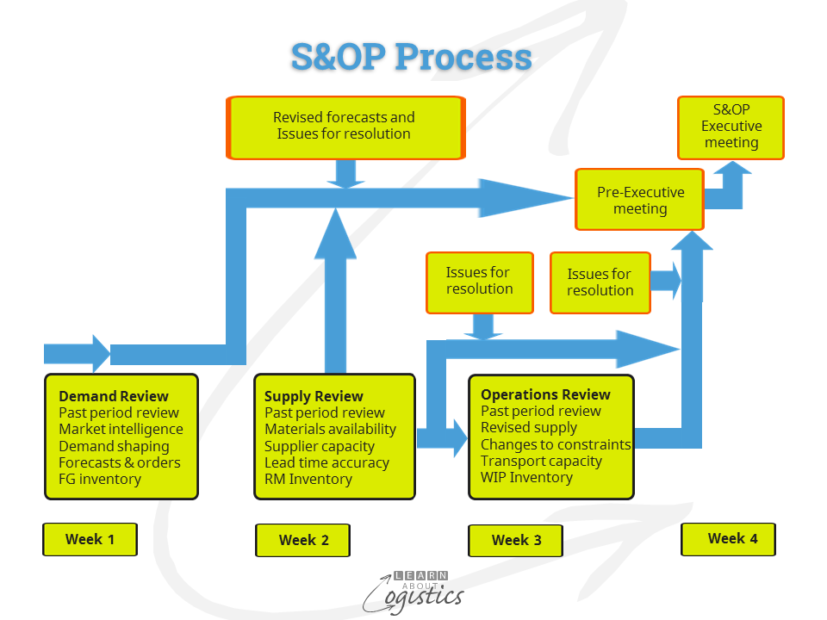

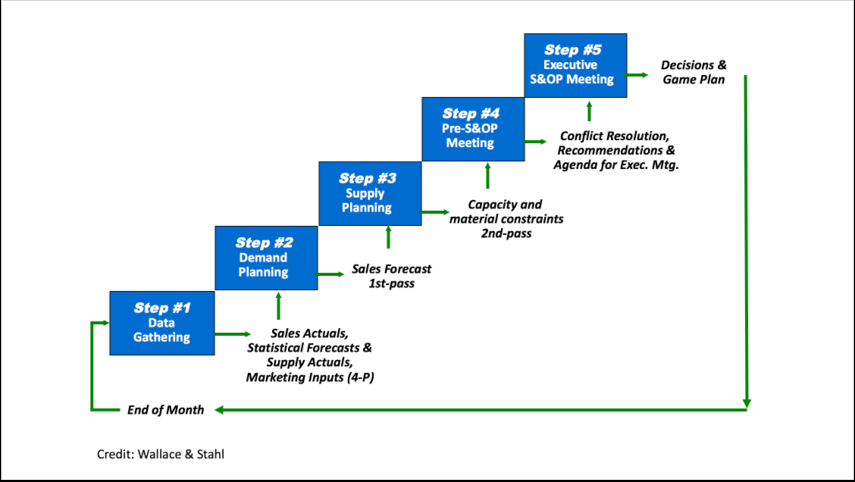

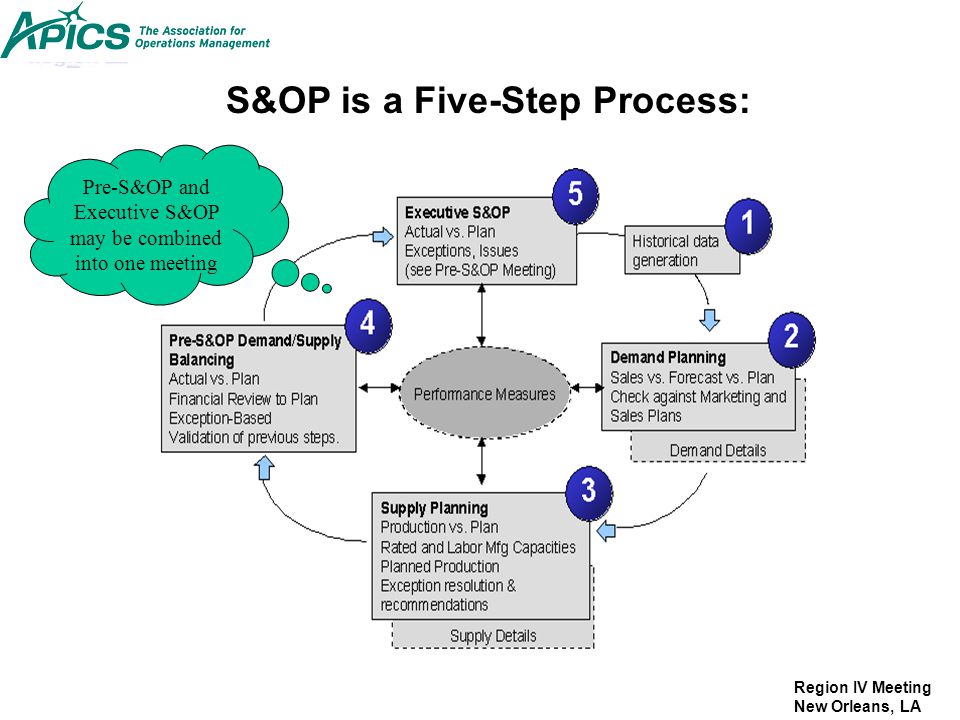

It is, however, a top level planning technique to provide overall rates of sales and production, and backlog and finished goods · S&OP is a fivestep process as illustrated in Figure 1 Figure 1 The S&OP Process S&OP is a process that coordinates different areas of the business to meet customer demand with the appropriate level of supply Implementation of S&OP should be undertaken in phasesThe S&OP includes all process to establish the estimated producti on plan at the t actical level, linking the strategic objectives of the company with the operational issues of the production

Wc Undor Gitar Supply Sales Chevroletlebanon Com

S Op Process Flow Chart Fusebox And Wiring Diagram Component Hut Component Hut Sirtarghe It

· Accurate supply planning S&OP software helps companies to be proactive, thus reducing lastminute shuffling in the distribution process Improved risk management When executed correctly, S&OP software ultimately drives improved cash flow, excellent customer satisfaction, and a longterm leveraged scalable process · Most importantly, it can better inform your sales and operation (S&OP) process The Importance of Demand Planning for a Successful Sales and Operation (S&OP) Strategy Demand planning plays an integral role in creating an effective S&OP strategy By using this multistep process, companies are better prepared to anticipate various kinds of demand and factor thoseHere's a rough overview of the difference A quick definition from APICS (The Association for Operations Management) describes discrete manufacturing as the production of distinct items such as automobiles, appliances, or

S Op Process

S Op Effectiveness Recommendations To Make The Leap Sales And Operations Planning Planning Process Capacity Planning

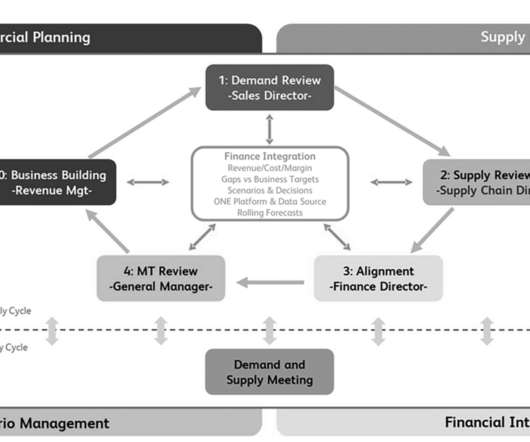

The most important S&OP vital sign is whether the executive leader is directly involved in the process by participating and providing leadership in each executive S&OP meeting In this context, the executive leader is the head of the organization in the position of CEO, president, managing director, general manager, or P&L owner S&OP is successful because it aligns planning acrossThe S&OP process enables the entire management team to understand the challenges confronting the organization and to act upon them in proper priority or focus Benefits Establishes operational plans consistent with the business plan;Steps to S&OP There are two distinct phases to S&OP 1) process design, and 2) process conduct In the design phase, all of the technical workings are engineered, and in the conduct phase S&OP is used as a business management process The following 10 steps describe how to go about these two phases Steps 15 are design and steps 610 are

S Op Five Steps To Get Started Supply Chain Shaman

Uncategorized Supplychainomics

Feb 25, 16 Recently I have been thinking about how the Sales & Operations Planning (S&OP) process fits in with the other planning processes within an Feb 25, 16 Recently I have been thinking about how the Sales & Operations Planning (S&OP) process fits in with the other planning processes within an Article from business2communitycom Integrating the S&OP Process GoProvides for crossfunctional planning ;Rusk Manufacturing Process Flow Chart Rusk manufacturing process consists of two stage baking where in the first baking stage is more like bread manufacturing and 2nd stage baking consists of tunnel ovens for large volume or rack ovens for smaller volumes Ebook on Bakery manufacturing process Article by Doug Morrow 1 Process Flow Chart Template Lean Six Sigma Bar Chart

Proposal Of A Model For Sales And Operations Planning S Amp Op Maturity Evaluation

Sap Ibp S Op In 21 Reviews Features Pricing Comparison Pat Research B2b Reviews Buying Guides Best Practices

Continually updates the production, financial, and sales plan;S&OP is a crossfunctional business process the S&OP process occurs within the business functions, and needs the combined contribution of several functions across the company, such as · Sometimes called Process diagram, procedure flowchart, process flow map or process map, process flow document or process flow documentation, process flow model or process design model, process flow analysis chart or process flow analysis map model, process document or process documentation Free Download Procedure Flowchart Software and View

Sales And Operations Planning Powerpoint Template Sketchbubble

Demand Management Springerlink

· From a good S&OP process you can get a huge number of things A realistic forecast of what your sales will be like you do this by asking questions of your customers and building trust ;The simple answer is that it is those metrics most vital to running your business SIOP aligns not only demand with supply but it also aligns the various business units and functional areas on one plan Therefore, there are standard metrics which are key to SIOP · The S&OP process will move to a weekly rhythm and the decision process will be built on scenarios that can be updated in real time This accuracy, granularity, and speed has implications for the other elements, such as service, supply chain costs, and inventory Systems will be able to detect the exception where a planner needs to jump in to decide Inventory Inventory

Sales And Operations Planning Relex Solutions

S Op Process

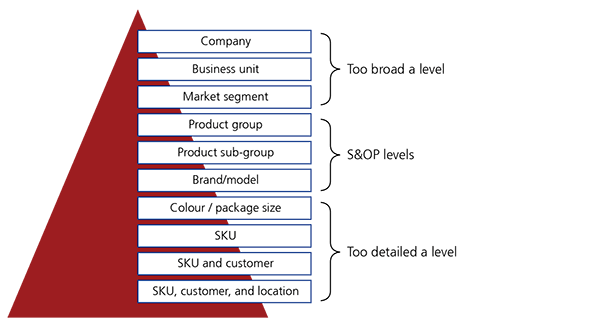

· S&OP Challenges Challenges Senior leadership support & "walk the talk" Achieving process compliance Identifying S&OP Champion or expert to lead implementation Clear definition and acceptance of roles and responsibilities, including defining specific objectives in employee appraisals Establishing S&OP meetings as the business priority Adapting the process to theOne of the primary benefits of S&OP is the planning structure Most forecasting processes generate forecasts only using an item's history In contrast, S&OP typically places that data in context, such as within a given market or customer It does so by providing data at an aggregate level across entire groups of customers or product familiesIn this article, we define a typical S&OP process and will explain how to implement the process According to IBF, S&OP is a process that coordinates different areas of the business to meet customer demand with the appropriate level of supply When establishing your process, it is important to consider who will be responsible for each step of the process You will also want to

Is S Op Excellence Slip Slidin Away Supply Chain Shaman

Sales And Operations Planning Overview Chapter 1 d

With a trusted S&OP process and leadership commitment lead to effective S&OP Because S&OP is a continuous process and reliant on new information, it improves from actual practice even at the risk of temporarily unfavorable outcomes TIP Identify optimal planning horizons by department and consider each department's planning needs In general, the more mature the S&OP practice, theRW S&OP (Flowchart) Use Creately's easy online diagram editor to edit this diagram, collaborate with others and export results to multiple image formats We were unable to load the diagram You can edit this template and create your own diagram · In my previous article entitled 'How to guide for S&OP Kick Off', we approached the roles and responsibilities within the S&OP process and the importance of each member knowing what they need to do at each step To assist and facilitate this task, we recommend the use of the RACI Matrix to quickly identify the roles and responsibilities of each individual/team in the S&OP process

23 S Op Ideas Sales And Operations Planning Supply Chain How To Plan

Sales Amp Operation Planning Of Beer Supply Chains

Integrated business planning (IBP) is a process for translating desired business outcomes into financial and operational resource requirements, with the overarching objective of maximizing profit and / or cash flow, while minimizing riskThe business outcomes, on which IBP processes focus, can be expressed in terms of the achievement of the following types of targets · For the S&OP process to be truly successful, it needs to be effectively integrated into the wider planning framework The S&OP process is only one part of the whole, itProcess, must engage the general manager and direct reports Otherwise, there will be a disconnect between there wishes and the information on the formal SIOP document SIOP is not a scheduling tool!

Educational Videos Ascm 19

Implement Supply Chain Planning System And Applications Learn About Logistics

Email Address Subscribe to Supply Chain Game Changer Featuring Our 10 Best Inventory Management Articles! · A company might follow one of a few slight variations of the stepbystep S&OP process The accompanying graphic shows a monthly fivestep process data gathering, demand plan, supply plan, preS&OP, and finally the executive S&OP meeting, where decisions are made Sales and Operations Planning Tips from the Pros · S Op Process Flow Chart Toyota 1992 Pickup Fuse Diagram Srd04actuator Yenpancane Jeanjaures37 Fr 41 Fantastic Flow Chart Templates Word Excel Power Point A Flow Chart Of Standard Operating Procedure In Cad Textile Scientific Diagram Process Flow Chart Template Style Hierarchy Flowchart 7 Piece Powerpoint Ation Diagram Infographic

Implementing A Sales Operations Planning S Op Process Plex Demandcaster

A Comprehensive Overview Of Sales And Operations Planning S Op

A closed loop improvement system to get a better forecasting & budgeting system; · Flow chart of receiving area activities scientific diagram tn 36 s op process flow chart wiring diagram accounting flowchart templates copedia how to maximize your law firm s efficiency by creating an operations flowchart pan group inc billing process flow chart receive bill adjust invoices ppt powerpoint ation pictures introduction templates Related Category Chart · The S&OP process allows allow critical resource shortages to be identified in advance so that appropriate action can often be taken to increase

Sales And Operations Planning S Op 101 Smartsheet

S Op Process Flow Biel 10 27 11

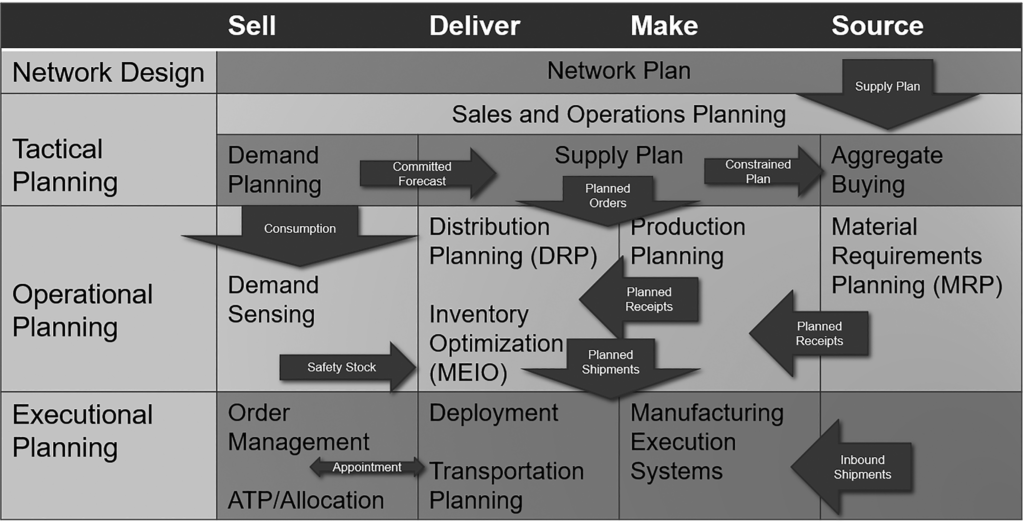

The S Op And The 3 Different Levels Of General Planning Based On Apics Download Scientific Diagram

8 Flowcharts For Traditional Planning Versus Advanced S Op Download Scientific Diagram

Demand Forecasting Process Flow Quantum Computing

Evaluation Of The Maturity Of The S Amp Op Process For A Written Materials Company A Case Study

Sales Amp Operation Planning Of Beer Supply Chains

S Op Made Good The Importance Of Investing In People Reuters Events Supply Chain Logistics Business Intelligence

Supply Planning Processes Options Analytics Oh My Plex Demandcaster

Evaluation Of The Maturity Of The S Amp Op Process For A Written Materials Company A Case Study

S Op Implementation Roadmap

S Op Process Flow Diagram 01 Kia Sephia Main Wiring Harness Fuses Boxs Corolla Waystar Fr

F2pl Bpexperts

S Op Process

Oracle Advanced Planning Command Center User S Guide

Sales And Operations Planning In Manufacturing Manage Collaboration Across The Entire Organization Tompkins Solutions

Sales And Operations Planning In Manufacturing Manage Collaboration Across The Entire Organization Tompkins Solutions

S Op Process Steps Adapted From Mentzer And Moon 09 Download Scientific Diagram

Sales And Operations Planning Explorescm

The 5 Most Common Sales Operations Planning Mistakes And How To Avoid Them Supply Chain 24 7

Sap Integrated Business Planning Ibp Sales And Operations Planning 18 Sap Blogs

Key Components Of Demand Driven Supply Chain Springerlink

Sales And Operations Planning Powerpoint Template Sketchbubble

28 Free Open Source And Top Flowchart Software In 21 Reviews Features Pricing Comparison Pat Research B2b Reviews Buying Guides Best Practices

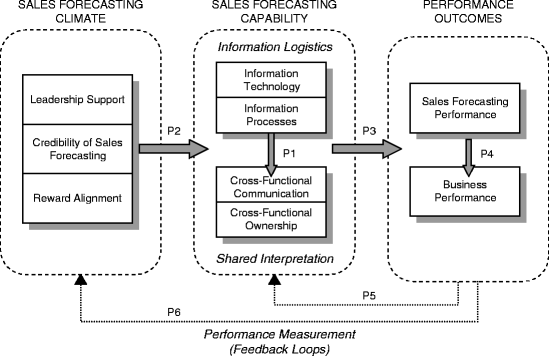

Framework For Measuring Performance Of The Sales And Operations Planning Process Emerald Insight

Oracle Advanced Planning Command Center User S Guide

Dp Vs S Op Process Flow

Implement The S Op Process For Supply Chain Success Learn About Logistics

Scs Analytics The S Op Umbrella

Achieve Excellence In Sales And Operations Planning Sapinsider

S Op Heuristics Flow Chart Download Scientific Diagram

S Op In Las Vegas Let S Learn Laugh And Be Entertained At The S Op Innovation Summit

Sales And Operations Planning S Op Is All About Balancing Supply And Demand Implement Consulting Group

What Is S Op How S Op Works Demand Planning Com

Key Components Of Demand Driven Supply Chain Springerlink

How To Invigorate The Supply Chain Demand Forecasting Process Processing Magazine

Competitive Advantage S Op Whitepaper Insights Publications Resources Gra

Framework For Measuring Performance Of The Sales And Operations Planning Process Emerald Insight

What Is S Op How S Op Works Demand Planning Com

Oracle Advanced Planning Command Center User S Guide

Achieve Excellence In Sales And Operations Planning Sapinsider

Supply Chain Graphic Of The Week The S Op Process

S Op Process

S Op Heuristics Flow Chart Download Scientific Diagram

Linear Business Processes Don T Work And There S A Better Way Cyber Supply Chain

Sales And Operations Planning Powerpoint Presentation Slides Presentation Powerpoint Templates Ppt Slide Templates Presentation Slides Design Idea

Sales And Operations Planning Relex Solutions

Implementing An Integrated Sales And Operations Planning Process

Data Flow Diagram Overview Youtube

Enterra Insights Nine Technologies Transforming The Supply Chain Part 2

Process Maps Flowcharts

S Op Process

What Is Sales And Operations Planning S Op Plex Demandcaster

File Monthly S Op Process Jpg Wikipedia

Sales Operations Planning Two Decades Of Learning At Basf Ppt Video Online Download

Sap Integrated Business Planning Ibp Sales And Operations Planning 18 Sap Blogs

Aggregate Sales And Operations Planning Ppt Download

Sales And Operations Planning Powerpoint Presentation Slides Presentation Powerpoint Templates Ppt Slide Templates Presentation Slides Design Idea

What Is S Op How S Op Works Demand Planning Com

What Is The Operating Model For S Op By Accenture Strategy Guest Blogger

Examples And S Op Supply Chain Brief

Sales And Operations Planning Powerpoint Template Sketchbubble

How To Select The Best Sales And Operations Planning S Op Software For Your Business In 21 Reviews Features Pricing Comparison Pat Research B2b Reviews Buying Guides Best Practices

Is S Op Excellence Slip Slidin Away Supply Chain Shaman

0 件のコメント:

コメントを投稿